A 3D printer workpiece sometimes needs to be cooled during printing,

to avoid deformation of the layer stack. This is needed for smaller models

and higher extrusion temperatures for lower-melting polymers (typically PLA).

Originally, a makeshift attachment for the E3D v6 hot end was made from steel wire and few drops of hot glue. This was judged insufficient.

Original makeshift version |  Original makeshift version |  Original makeshift version |  Original makeshift version |

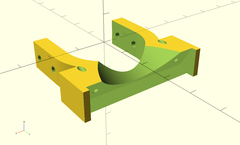

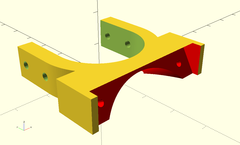

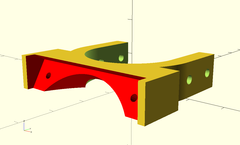

A part was drawn in OpenSCAD, using a rough approximation of the

hot end fan attachment. A drawing of a 40mm fan was also made, with

projectings of holes and rotor, to be subtracted from the attachment

template.

Rendered model |  Rendered model |  Rendered model |

Horizontal mounting holes were made in the clamp pads. All holes were after printing drilled to 2.5mm and cut with M3 thread.

For printing, PLA at 0.4mm layer thickness was used.

Fan holder, as printed |  Fan holder, as printed |  Fan holder, cleaned up |  Fan holder, cleaned up |

Fan holder, cleaned up |

The fan mount holes hold thread well.

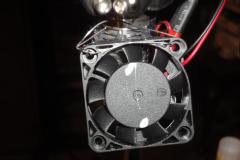

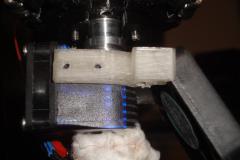

Fan mounted on new holder |  Fan mounted on new holder |  Fan mounted on new holder |  Holder in place |

The clamp holes were intended to host screws that'd squeeze the head fan attachment. It turned out to be insufficient. A hole had to be drilled directly to the plastic part with the fan, and a M3 thread tapped in. The same was done from the other side. One screw was used in its original clamp duty, to fix the holder in the proper angle.

Mount hole drilled |  Holder attached |  Holder attached |  Holder attached |

Holder attached |  Holder attached |  Holder attached |